What are Air Handler Units? How do they work? And where are they typically located in a given HVAC Project?

As part of the HVAC System, Air Handling Units or AHU are installed in medium to large industrial and commercial buildings such as in factories, malls, hotels, hospitals, office spaces, educational institutes, and industrial plants. These important units are placed either in the basement, rooftop or on the floors such as on the ground floor. Depending on the load, some buildings may have AHUs installed at 2 or 3 places such as on the rooftop, and in the basement. However, if the load is less, then, a single AHU located at the basement or rooftop can serve the purpose. In a large building, different units can be used to serve different floors or server rooms or office areas or toilets, etc. However, for a small application, a single AHU can serve the complete building itself.

The Air Handling Unit firstly conditions the air and then subsequently distributes this conditioned air within a given building.

This is how an AHU works:

- They suck fresh atmospheric air from the outside, and then, firstly clean this atmospheric air by leveraging various kinds of air filters.

- And then, depending on the application, an AHU heats or cools the clean air.

- Thereafter, the air is humidified or dehumidified.

- And the last step in this whole process is to distribute the air to various parts of the building through ductwork.

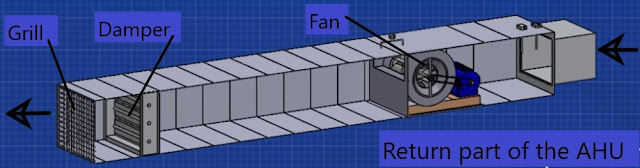

- The AHU will also have return ductwork to suck the unclean or dirty air out from the rooms or other parts of the buildings. Therefore, there are always 2 kinds of ductwork in a given building. The 'supply' ductwork to distribute the clean air inside the building. And the 'return' ductwork to suck out the dirty air back from the building to the Air Handling Unit wherein a fan flushes-out this dirty air in the atmosphere.

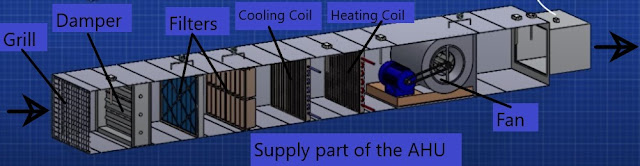

Various Stages in a typical Air Handler Unit:

1. Grills are used at the inlet of the 'supply' ductwork and at the outlet of the 'return' ductwork in order to stop foreign objects or birds or reptiles or other animals from entering the AHU. These grills are an extremely important piece of an air handler unit from a performance perspective as well as from a longevity perspective.

2. The next stage is the dampers stage at the ‘supply’ and ‘return’ ductwork. These dampers comprise multiple layers of metal that can rotate. The dampers can be closed to stop air from entering the 'supply' ductwork or can be opened to allow atmospheric air to enter the 'supply' ductwork. Similarly, dampers can be closed to stop air from leaving the 'return' ductwork or can be opened to let the dirty air out from the 'return' ductwork.

3. The next stage in the AHU unit is that of the filters. As the name suggests, air filters remove dirt and dust from the incoming air entering the Air Handler Unit. Without these filters, the dust would accumulate in the AHU as well as enter the building along with the delivery air. This delivery air will be inhaled by the people inside the building. Therefore, filters are an essential part of an AHU. Generally, 2 filters are used to remove as much dirt and dust from the air as possible. The first filter is a panel filter that helps in removing larger dust particles. The second filter is a bag filter that helps in removing smaller dust particles. Pressure sensors are used across the filters in order to sense how dirty the filters are. Based on the input received from the pressure sensors, the technicians can change the filters.

4. Once the air passes through the filters stage, it goes through the cooling or heating coil stage. As the name suggests, depending on the purpose, the cooling coil gets switched on for cooling purposes while the heating coil gets switched on for heating purposes. These coils are nothing but the heat exchangers wherein hot or cold fluid flows. This fluid is generally heated or chilled water or refrigerant.

5. Thereafter, a fan is placed inside the AHU. This fan sucks the air from outside. This air passes through the stages of grills, dampers, filters, and coils as explained above, and is then delivered inside the building. The fan can be a conventional AC induction motor fan or EC fan (BLDC fan). These days, EC fans (BLDC fans) are deployed because of higher energy-efficiency and better control functions. A pressure sensor is deployed across the fan in order to detect the smooth working of the fan. Based on the input received from the pressure sensor, the technicians can change the fan or repair the fan as needed.

6. The final ductwork thereafter sends the air to various parts of the building. The 'return' ductwork allows the unclean air from the building to return to the 'return part of the AHU'. This unclean air is flushed out into the atmosphere. The 'return part of the AHU' just comprises a fan and a damper.

This is the most standard explanation of an Air Handler Unit. However, in the 'supply part of the AHU', some additional coils may be used. Coils such as frost protection coil and humidifier/dehumidifier coil. In colder climates, a frost protection coil is used to preheat the incoming air. This frost protection coil is basically an electric heater. In tropical climates, humidity control is needed and for that, a humidifier coil is used.

The 'supply part' and the 'return part' of the AHU can be placed separately in different locations or they can be placed adjacently. If they are placed adjacently, then, heat recovery is possible and that makes the whole AHU installation much more energy-efficient.

Here is an image showcasing the 'Return part of the AHU' as well as the 'Supply part of the AHU'.

Supply Part of the AHU that delivers conditioned air inside the building: